AUTOMATION SOLUTIONS:

Choosing the Right

High-Speed Packaging Machinery for your Operations

Tishma® Technologies (an IPG® company) has been an innovative leader in the field of packaging automation for more than 40 years. As designs and developments have advanced with time, our team has been at the forefront of modernization and invention. Today, our packaging automation machines are used by a variety of sectors on a global scale, from food and beverage (F&B) companies to medical and pharmaceutical suppliers.

We complete all design, fabrication, and assembly work in-house, allowing us to maintain strict control over our solutions. Through our quality craftsmanship, innovation, and access to top-notch technology, we create modular designs to help companies fulfill their packaging needs, allowing them to meet client demands and maintain compliance with strict industry regulations.

Market Segments Served

unlock new efficiencies. Some of the market segments we serve include:

- Consumer Packaged Goods (CPG)

- Omni-Channel Retail and E-Commerce Distribution

- Food and Beverage Production

- Pharmaceutical and Nutraceutical Production

- Fulfillment & Warehousing Distribution

Within these sectors, our options include:

- Candy and snacks packaging automation

- Medical supplies packaging

- Pharma bottle packaging

- Pharmaceutical packaging

In all of these sectors, we offer high-speed, state-of-art primary packaging machines, secondary packaging machines,

and tertiary packaging machines.

In the candy and snacks market, brands use our equipment to pack a variety of confectionery products including candy

blisters, free-flowing candies, candy stick packs, chocolates, chewing gums, and more. Our packaging solutions for

medical and pharmaceutical supplies cover products such as masks, gloves, goggles, and other types of personal

protective equipment (PPE), as well as pill/tablet blisters, vials, syringes, and related gear.

Download our eBook Today!

Our guide is an invaluable resource for your team. It helps address common questions and overcome objections when selecting the perfect duct tape for various tasks. Keep this eBook handy to ensure you always make informed decisions.

For the pharmaceutical and nutraceutical industries, we design vertical and horizontal cartoning and case-packing solutions for secondary packaging products that include plastic and glass bottles of any shape. This includes widemouthed bottles, round bottles, pharma cylinders, and other items. We also develop automation-driven pharmaceutical packing solutions for vials, ampoules, stick packs and sachets - all in line with the latest industry standards.

Types of Packaging Machines

We offer Cartoning, Case Packing, , Vision Inspection, Void Fill, Robotics and Palletizing machines designed to meet the needs of every business, from small-to-medium companies or startups to large-scale enterprises.

We designed our cartoners, case/tray packers, and case erectors to assimilate seamlessly into any packaging line. Our products meet a range of business needs, from vacuum-assisted case feeders that reduce downtime to robotic arms that perform a myriad operations at once.

Cartoning Systems

We offer semi-automatic and fully automatic machine solutions ensuring complete control over all aspects of handling. Our machines can be customized to include volumetric filling, scales, auger-interfaces, robotic loading, and custom infeeds. They are

We offer semi-automatic and fully automatic machine solutions ensuring complete control over all aspects of handling. Our machines can be customized to include volumetric filling, scales, auger-interfaces, robotic loading, and custom infeeds. They are

available on both vertical and horizontal configurations and off speed outputs ranging from 500-1000 CPM. Our solutions are designed to accommodate various carton and closure formats.

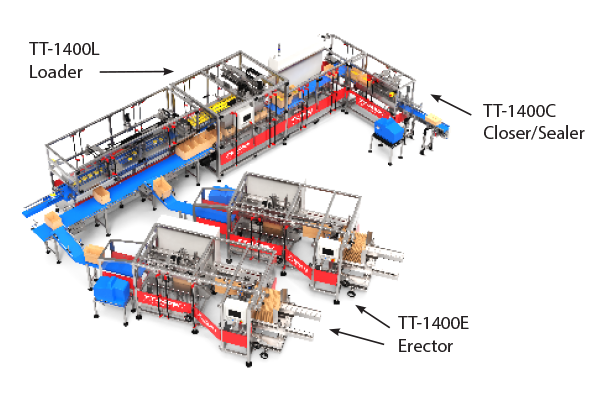

Case Erectors & Packers

Tishma manufactures a variety of modules that include random robotic case forming and a stainless steel uniform erecting module that can be fully integrated with our loading/case packing module. These systems can showcase high speed case output that can range from 10-30 cases per minute in both vertical or horizontal loading formats. They can handle a wide range case sizes with servo-driven and robotic collation. Closure options can vary from water-activated tape, pressure-sensitive tape, or hot melt glue.

Tishma manufactures a variety of modules that include random robotic case forming and a stainless steel uniform erecting module that can be fully integrated with our loading/case packing module. These systems can showcase high speed case output that can range from 10-30 cases per minute in both vertical or horizontal loading formats. They can handle a wide range case sizes with servo-driven and robotic collation. Closure options can vary from water-activated tape, pressure-sensitive tape, or hot melt glue.

Vision Systems

SafeSeal-AI - Automated Machine Vision Inspection

SafeSeal-AI - Automated Machine Vision Inspection

We harnessed the power of AI to create a user-friendly in-line heat seal inspection system, simplifying and improving quality control in the food and medical industries. Our

deep-learning AI tools use thermal images to identify and alert teams on sealing defects, including ones that most rules-based vision tools or inspections typically miss.

SafeSeal-AI is our computer-based, turnkey inspection system for heat-sealed trays and packaged products. It includes every component required to perform accurate, reliable inspections, operating at a rate up to 300 scans/minute.

Perfect Packer - Void Fill System

Perfect Packer - Void Fill System

Our Perfect Packer Automated Void Fill System with AI Technology, reduces the human decision making around void fill need and amounts, while optimizing order fulfillment and void fill utilization.

With features that include 3D sensors, a high-resolution camera, and a state-of-the-art analytics display, the Perfect Packer uses artificial intelligence (AI) to fine-tune void fill amounts every time. Production data can be exported or WMS integrated for further analysis.

Auto Mailer System

Auto Mailer System

AMS - Auto Mailer System

The AMS - Auto Mailer System is an industry-leading design that automatically creates a paper, mailable package around each order. Right-sizing flow wrap technology allows us to tailor the package size according to the product need. It further offers options for Ink Jet ID barcoding, labeling and WMS Integration.

Palletizers

Our palletizing solutions equip companies to quickly and safely stack cases of goods. Our lines include many different solutions for various applications, including robotic, gantry, and collaborative palletizer systems.

OpenStack

OpenStack

OpenStack is our compact, portable palletizer. Its nimble operations and open, guardless layout allow teams to stack your product and move pallets out of the door as quickly as possible, with minimal footprint and operator involvement required.

TetriStack TetriStack is our versatile, modular robotic palletizer. It features a compact, lightweight design that can be adapted to a wide variety of of packaging applications that may include multiple infeeds and outfeeds, slip sheet handling, pallet magazines, and custom end-of-arm-tooling design.

TetriStack is our versatile, modular robotic palletizer. It features a compact, lightweight design that can be adapted to a wide variety of of packaging applications that may include multiple infeeds and outfeeds, slip sheet handling, pallet magazines, and custom end-of-arm-tooling design.

E-CO Flex Modularity Solutions

With our e-commerce machinery, we leverage right-size technology to adjust our packaging solutions to meet specific product needs. This approach allows us to reduce our labor, waste, and consumption without sacrificing product quality or customer satisfaction.

With our e-commerce machinery, we leverage right-size technology to adjust our packaging solutions to meet specific product needs. This approach allows us to reduce our labor, waste, and consumption without sacrificing product quality or customer satisfaction.

Our exclusive distribution relationship with IMA S.p.A. provides us the E-CO Flex Automated Packaging Station. With individually designed Modules for forming, packing, conveying, top case closing with or without downsizing and is available using IPG’s premium quality water-activated or pressure sensitive tapes. ONE E-CO Flex can replace TEN conventional pack stations!

- Forming Module + Box First/Box Last Custom Packing Conveyor layout + Top Closer or

Sealmatic = A state of the art order fulfillment system based on your process needs

E-CO Flex SealMatic

E-CO Flex SealMatic

SealMatic will receive cases and adjust automatically to the required width and height. Once accepted, the machine folds down the top 4 flaps and applies wateractivated tape (WAT) to the top and bottom of the case completing the closure process. It is also configured with a PST option and to allow for processing of SIOC (ship in own container) units. Incoming cases are scanned and if identified as SIOC, will automatically by-pass the flap folding and taping functions.

Integrations and Custom Packaging Systems

We’re industry leaders because we integrate advanced technology and automation into every aspect of our packaging

systems. This enables us to meet complex needs across diverse applications, from carton or case erecting, product

handling, grouping, filling and loading, in vertical or horizontal formats, bundling, palletizing, line tracking through to

stretch wrapping.

Our robotic solutions leverage multi-axis arms to address challenges in design, deployment, prototyping, integration, and

maintenance. We can integrate these throughout a line to further automate process.

For labeling or coding, we integrate embossing, ink jet printing, or other labeling features, particularly beneficial for

industries like pharmaceuticals, where strict coding, labeling, and serialization are required. Our equipment is also built

for washdown and sanitary environments, meeting the rigorous standards of sectors like F&B and pharmaceuticals. It

withstands high-pressure sprays and heat while protecting electrical components in waterproof enclosures.

We specialize in machine vision systems that enhance efficiency, accuracy, and quality control. This includes defect

detection, label verification, and product sorting. Streamlining operations, reducing waste, and ensuring compliance with

customer industry standards.

Our products are intuitive, user-friendly, and comply with industry regulations. All systems undergo quality, safety, and

sanitization testing, supported by risk assessments and GMP/GAMP compliance. We provide thorough documentation to

ensure full adherence to all GMP and GAMP standards.

Built-in Machine Safety

High-tech packaging solutions like ours can be dangerous if used improperly. That’s why we designed them with built-in controls to support user safety and prevent accidents.

Guarding, Interlocks

Guarding, Interlocks

Guarding software supports safe and accurate end of line packing machines, helping to control where the robotic arms go. In addition, we also install safety electrical interlocks to prevent machines from operating or starting up in an unsafe environment.

Electrical

We take electrical safety seriously, and we’re transparent about our

compliance with industry-leading standards, including NEMA and UL.

NEMA

The National Electrical Manufacturers Association (NEMA) has defined the standards that North American manufacturers must use when deploying different grades of electrical enclosures in industrial applications. Our solutions are NEMA compliant.

UL

We also follow all applicable Underwriters Laboratories (UL) guidelines when developing, testing, and deploying our components, materials, and systems. These are the most widely known and followed standards in the electrical industry.

Washdown and Sanitary

We know that some industries, such as the F&B and pharmaceutical sectors, require extremely clean and sterile environments, even in the warehouse. Our equipment can stand up against washdown and sanitation procedures, including high-pressure spray or heat, without losing its appearance or functionality.

Electrical components are safely concealed in washdown, waterproof electricalenclosures meet NEMA requirements.This means proper precautions are in place to ensure splashes and streams from a hose don’t interfere with its

capabilities.

Quality, Safety, and Compliance

We design our products to be intuitive, high-quality, and user-friendly. We also ensure they align with industry regulations and requirements. All our products are quality, safety/sanitization tested and further supported by risk assessments, GMP & GAMP’s compliance and IQ/OQ qualifications.

Overall Adherence to GMPs

Our team will draft and compile documentation to prove that all aspects ofour machine development process comply with Good Manufacturing Practice (GMP) and Good Automated Manufacturing Practice (GAMP 5) standards.

Post Sales and Service Support

Every Tishma machine goes through rigorous testing before being considered production ready.

These tests are checklist-based with clear criteria based on customer application & shared with customers. No machine “leaves” Tishma Technologies without passing all tests.

These tests are checklist-based with clear criteria based on customer application & shared with customers. No machine “leaves” Tishma Technologies without passing all tests.

- Safety & Sanitization compliance

- Qualifications (IQ/OQ)

- Specifications: GMP and GAMPS compliance

- Risk Assessment

- Factory Acceptance Test (FAT)

Auxilary Services

When you partner with Tishma Technologies, your experience doesn’t end at the point of sale. We provide comprehensive

auxiliary services for WMS and full integration services to make sure our automated solutions fit your needs long into the

future.

Sales Support and Maintenance

Before your machine even ships, our service & technical support teams are already part of the project from FAT, to

SAT, through installation and long after to keep your equipment running at peak performance levels. Our goal is to

avoid failures, but if something does go wrong, our team is here to get you running as fast as possible. With over 300

mechanical, electrical and software teams and technicians located around the country.

When you partner with Tishma Technologies, your experience doesn’t end at the point of sale. We provide comprehensive

auxiliary services for WMS and full integration services to make sure our automated solutions fit your needs long into the

future.

On-Site and Remote Support

We offer a variety of professional services from on-site field service, equipment customer service, remote assistance as

well as consultation and advice to solve your packaging equipment and service needs.

Spare Parts, Preventative Maintenance Programs and On Demand Field Service support

We’re dedicated to being a full-service supplier for our clients all around the world. We will support you before, during,

and after your installation, providing services that include:

- Pre-assembled maintenance kits

- Part number engraving for easy identification

- Specially designed retrofit kits

- Audits and equipment rebuilds

to keep thousands of machines up and running around the world.

Discover Our Full Line of Packaging Automation Machines

There's a reason why clients around the world have trusted Tishma Technologies for more than four decades. Our best practices, tech-centric design approach, and commitment to quality set us apart from our industry competitors.

We're the leading experts in packaging automation machines, and we're continually designing new solutions to meet evolving client needs.