Perfect Packer

Automated Void Fill With A.I. Technology

With its user-friendly design, Perfect Packer is easy to operate and a perfect addition to your order fulfillment packing line. No more guesswork or wasted fill – Perfect Packer takes care of everything automatically.

Fill out this form to speak with our experts about how the Perfect Packer can improve your order fulfillment automation.

Watch the Perfect Packer in action...

Are You in Need of Void Fill Materials?

Explore our full range of protective packaging products.

Optimize Void Fill with Data and AI

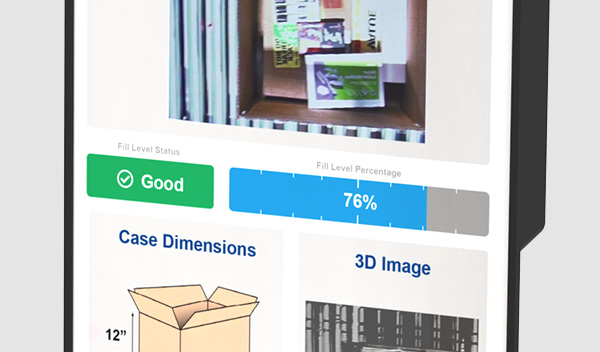

Perfect Packer dispenses the optimal amount of void fill cushioning material for every case. 3D imaging sensors scan each case to determine the amount of empty space within. Pre-determined % of fill levels define how much filler material is now automatically dispensed. This ensures control over optimal void fill levels. The Perfect Packer minimizes waste and damages, while maximizing end of line throughput with the least amount of operator involvement.

Dunnage Control

Control your fill percentage remotely and update your process immediately. Data is collected and reported on void fill percentages per case size.

Analytics Display

Advanced data analytics display provides up to the minute visual reference of real time production and void fill data.

Vision Imaging

One high resolution 12 Megapixel camera with advanced high color graphics with two 3D sensors capture every detail of your packing process.

Features and Benefits

- Deep Learning - Advanced identification on up to 20 products.

- End of line solution for "box first" or "box last" e-fullfillement.

- Reduce labor by eliminating and consolidating pack stations.

- Increase throughput by pacing the line and reducing operator decision making.

- Analyze and optimize case sizes for DIM weight and freight cost reductions.

- Photo storage for product damage or pilferage claim tracking.